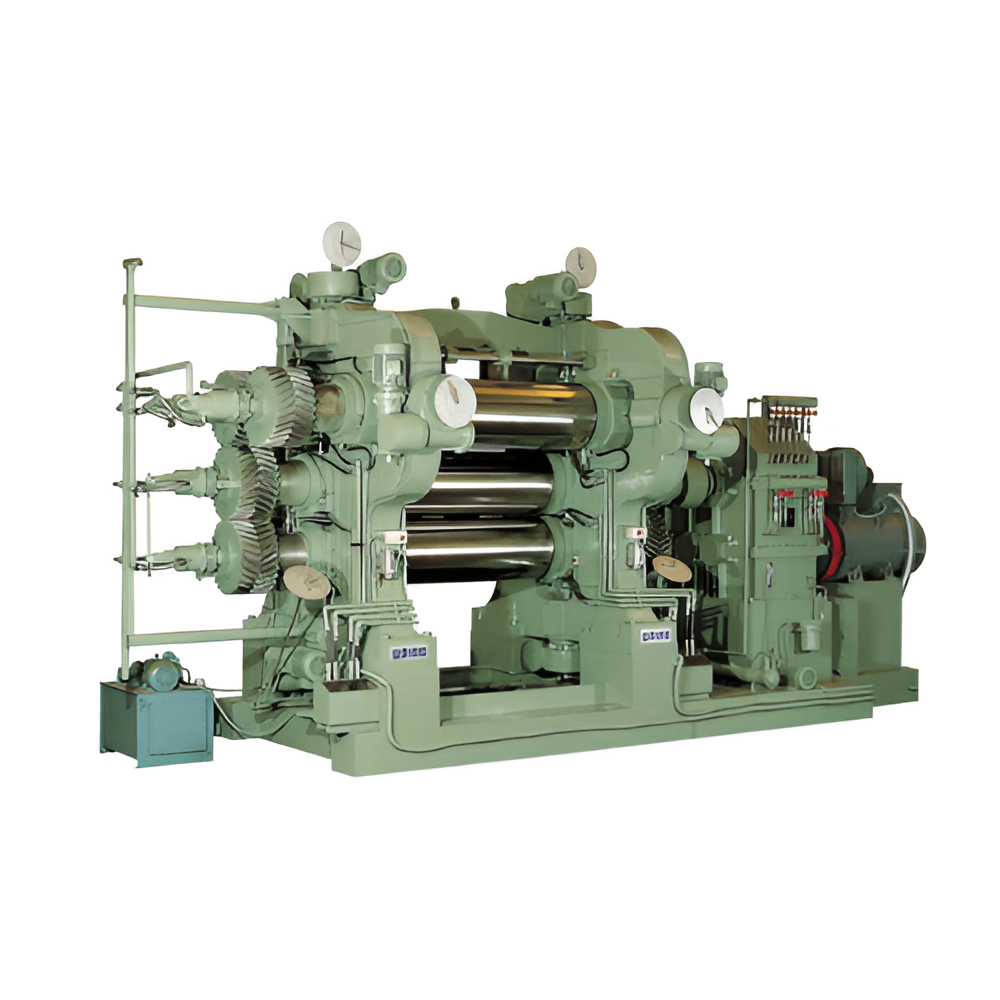

Calendar Machine 0

Precision calendaring machines for uniform rubber sheet thickness and width. Engineered with adjustable rollers and control systems for maximum accuracy.

InquiryOverview:

Calendars are used to produce uniform rubber sheets or to coat fabric with rubber. Rubber Front offers 2-roll to 4-roll configurations with precision control systems for thickness and surface finish.

Key Features:

· Precision roll alignment and temperature control

· Servo-driven adjustment and hydraulic loading

· Fabric guiding and tensioning systems

· Optional inline embossing or lamination

Applications:

Ideal for conveyor belt plies, rubber sheeting, and fabric coating processes.

✅Advantages and Comparison with Competitors

Front Rubber Calendar Machine

· ✅ Custom roll configurations (2R, 3R, 4R) for flexible applications

· ✅ Accurate thickness control via hydraulic gap setting

· ✅ Multi-zone heating system ensures uniform temperature

· ✅ Optional fabric guiding and tensioning system

· ✅ Heavy-duty frame for vibration-free operation

❓ Frequently Asked Questions (FAQs)

Q1: What is the difference between 2-roll, 3-roll, and 4-roll calendars?

A: More rolls offer greater control over thickness, layering, and surface quality. 4-roll systems are ideal for coating fabrics and laminating multiple layers.

Q2: Can the machine be used for both sheeting and fabric coating?

A: Yes, our calendar machines are designed for versatile applications including sheet extrusion, ply coating, and textile integration.

Q3: How is thickness controlled during calendaring?

A: Through hydraulic or mechanical roll gap control, with feedback from laser sensors or thickness gauges (optional).

Q4: Is the machine suitable for continuous 24/7 operation?

A: Yes, it's engineered for industrial-grade reliability with continuous operation capability and minimal downtime.

| Specification | Details |

| Number of Rolls | 2, 3, or 4 (customizable) |

| Roll Diameter | 250 – 600 mm |

| Roll Width | 800 – 2000 mm |

| Roll Surface Finish | Polished / Hard Chrome / Teflon Coated |

| Roll Material | Chilled Cast Iron / Alloy Steel |

| Roll Alignment Type | Horizontal / Inclined / Vertical |

| Heating System | Electrical or Steam |

| Temperature Control | PID-based, Multi-zone |

| Roll Pressure System | Hydraulic or Mechanical |

| Speed Control | Inverter-driven, 0–60 m/min |

| Automation | PLC + HMI Touchscreen |

| Optional Units | Embossing / Lamination / Fabric Guide |