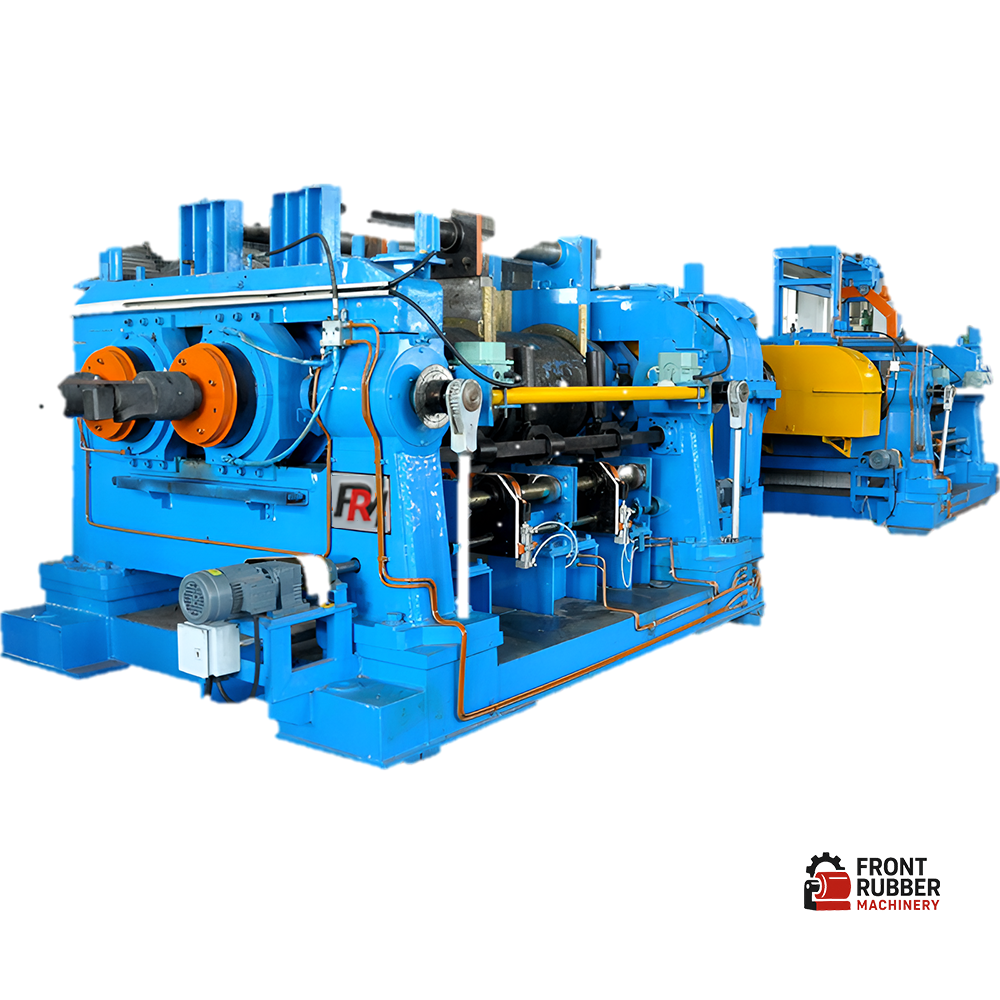

Open Mixing Mill 0

Robust open mills designed for consistent rubber sheet preparation. Available in multiple roll sizes and configurations with optional automatic feeding and cutting systems.

InquiryOverview:

Open Mixing Mills are used for refining rubber compounds, sheeting, and warming-up. Our machines provide optimal mixing action with excellent visibility and manual control for precision.

Key Features:

· Chilled alloy steel rollers (grooved or plain)

· Variable friction ratio and motor speed

· Nip gap adjustment via handwheel or hydraulics

· Emergency stop and safety bar system

· Optional stock blender for auto mixing

Applications:

Essential for preparation before calendaring, sheet forming, and compound adjustment.

Advantages and Comparison with Competitors

Front Rubber Open Mixing Mill

· ✅ Heavy-duty frame and base for long-term durability

· ✅ High surface hardness of rolls (up to HS75)

· ✅ Stable and quiet gearbox with high torque transmission

· ✅ Option for automatic stock blender integration

· ✅ Emergency reverse and quick-stop system

❓ Frequently Asked Questions (FAQs)

Q1: What is the purpose of the friction ratio between the rolls?

A: It helps in shearing and stretching the rubber, enhancing compound dispersion during mixing.

Q2: Can I adjust the nip gap while the machine is running?

A: Yes, with motorized or hydraulic adjustment models, you can control the nip gap in real time.

Q3: What safety features are included?

A: Our mill includes an emergency stop bar, safety guards, motor brake, and reverse rotation on accident trigger.

Q4: How long do the rolls last?

A: With proper cooling and cleaning, the rolls can last 5+ years without regrinding.

| Specification | Details |

| Roll Diameter | 200 – 660 mm |

| Roll Length | 450 – 1800 mm |

| Motor Power | 15 – 150 kW |

| Friction Ratio | 1.15:1 – 1.30:1 |

| Nip Adjustment | Manual, Motorized, or Hydraulic |

| Cooling Method | Water-cooled Rolls |

| Roll Material | Chilled Cast Iron / Alloy Steel |

| Safety Features | Emergency Stop Bar, Safety Cover |

| Optional Features | Stock Blender, Temp. Sensor, PLC |

| Mixing Capacity | Up to 300 kg/batch (based on model) |